Market Overview:

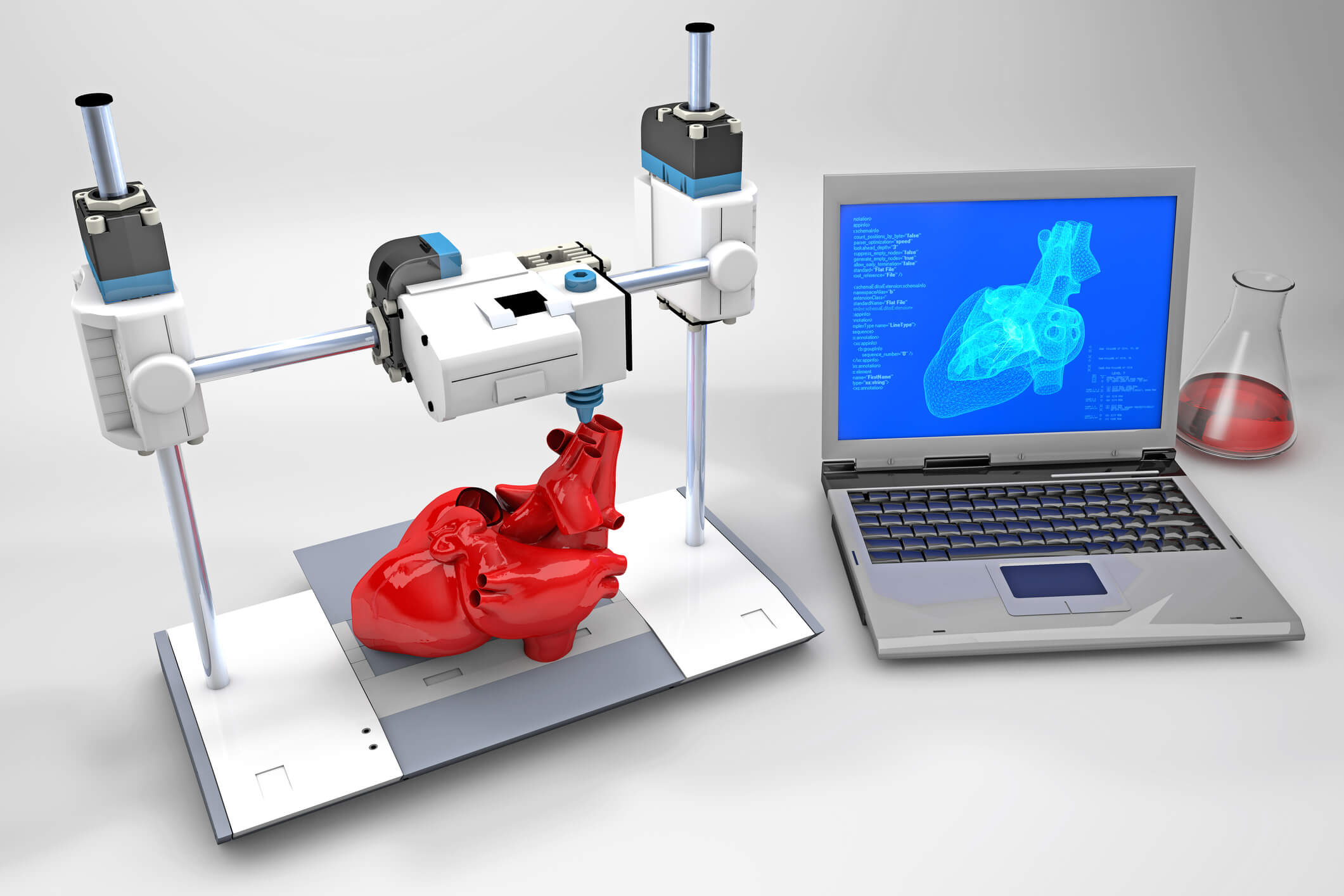

The 3D Printing in Healthcare Market is experiencing strong expansion, fueled by Rising Demand for Customized Medical Solutions, Technological Advancements in Bioprinting, and Increasing Application in Surgical Planning and Implants. According to IMARC Group's latest research publication, "3D Printing in Healthcare Market Report by Material (Polymer, Metals, Ceramic, Organic),Technology (Droplet Deposition, Photopolymerization, Laser Beam Melting, Electronic Beam Melting (EBM), Laminated Object Manufacturing, and Others), Application (External Wearable Devices, Clinical Study Devices, Implants, Tissue Engineering), End User (Medical and Surgical Centers, Pharmaceutical and Biotechnology Companies, Academic Institutions), and Region 2025-2033", The global 3D printing in healthcare market size reached USD 3.4 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 11.1 Billion by 2033, exhibiting a growth rate (CAGR) of 12.5% during 2025-2033.

This comprehensive analysis highlights industry size, trends, market share, and key growth drivers along with regional forecasts. The report consolidates insights from various data sources and research findings, offering a detailed overview of market dynamics including emerging technologies, challenges, and competitive strategies. Additionally, it presents a regional market breakdown and a clear view of the competitive landscape.

Download a sample PDF of this report: https://www.imarcgroup.com/3d-printing-in-healthcare-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends and Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Growth Factors in the 3D Printing in Healthcare Market:

- Rising Demand for Customized Medical Solutions

The shift toward patient-centric care is accelerating the adoption of 3D printing in healthcare. Unlike conventional mass production, 3D printing allows for on-demand creation of tailor-made medical solutions that precisely match patient anatomy and clinical requirements. Custom prosthetics and orthotics can now be produced more quickly and affordably, improving mobility and comfort for patients with physical impairments. In surgical environments, patient-specific guides and instruments enhance precision and reduce the risk of complications. For instance, customized jigs used in orthopedic surgeries help align implants more accurately, reducing post-operative issues. The flexibility of 3D printing also supports rapid prototyping and iterative design, enabling healthcare providers to innovate faster and respond swiftly to complex cases.

- Technological Advancements in Bioprinting

Bioprinting has emerged as one of the most promising frontiers in medical research. Using cells, hydrogels, and growth factors as "inks," bioprinters can fabricate complex tissue structures, including skin, cartilage, and even vascularized tissues. These bioprinted tissues are being used in research to study disease models and drug responses with higher biological relevance than traditional 2D cultures. Progress in multi-material printing and precise cell placement is enhancing tissue function and viability, laying the foundation for future breakthroughs in organ regeneration. Although fully functional 3D-printed organs remain in development, bioprinting is already showing tangible benefits in wound healing, reconstructive surgery, and the development of biologically compatible scaffolds for tissue growth.

- Increasing Application in Surgical Planning and Implants

The use of 3D-printed anatomical models for surgical planning has transformed complex procedures across orthopedics, cardiology, maxillofacial surgery, and neurosurgery. Surgeons can now visualize patient anatomy in three dimensions, simulate operations, and rehearse procedures using life-like replicas. This enhances surgical accuracy, shortens procedure times, and improves patient outcomes. Beyond planning, the production of implants tailored to individual anatomy—such as spinal cages, cranial plates, and dental restorations—is gaining momentum. These personalized implants offer better fit, reduced surgical trauma, and faster healing times. Hospitals and clinics are increasingly investing in in-house 3D printing capabilities to support real-time design and production, integrating the technology into daily clinical workflows.

Key Trends in the 3D Printing in Healthcare Market:

- Integration of AI and Imaging Software

The convergence of artificial intelligence with 3D printing is reshaping digital health design. AI algorithms can automatically segment medical imaging data (like CT or MRI scans), identify abnormalities, and generate optimized 3D models for printing. These tools help clinicians and designers save time while improving accuracy and consistency. AI also contributes to topology optimization, ensuring devices are lightweight yet structurally sound. For example, AI can be used to create a prosthetic limb that maximizes comfort and strength while minimizing material usage. This synergy between AI and 3D printing is especially useful in time-sensitive or resource-limited medical scenarios.

- Growing Adoption in Education and Training

3D-printed anatomical models are increasingly being adopted by medical and dental schools to provide hands-on learning experiences. These models replicate real-life anatomical variations and pathological conditions, offering a safer and more practical alternative to cadaveric dissection. Surgeons-in-training can practice incisions, implant placement, and procedural steps on models designed to simulate real clinical conditions. Customization allows educators to recreate rare or complex cases, improving diagnostic and procedural confidence. This trend is especially valuable in remote or resource-limited regions, where access to traditional training tools may be limited. It also fosters interdisciplinary learning by involving engineers, designers, and healthcare professionals in collaborative problem-solving.

- Eco-Friendly and Cost-Effective Printing Materials

Sustainability and cost-efficiency are becoming integral to healthcare operations, and the development of new 3D printing materials reflects this priority. Biodegradable polymers, plant-based resins, and recycled thermoplastics are being used to create disposable medical models, temporary implants, and surgical tools. These materials not only lower the environmental footprint of production but also reduce manufacturing costs, especially for one-time-use items. Water-soluble and dissolvable supports further reduce waste during the printing process. Additionally, advancements in material science are enhancing the mechanical properties and biocompatibility of affordable options, enabling their use in regulated clinical environments. This democratization of materials is making 3D printing more viable in public healthcare and emerging markets.

We explore the factors propelling the 3D printing in healthcare market growth, including technological advancements, consumer behaviors, and regulatory changes.

Leading Companies Operating in the Global 3D Printing in Healthcare Industry:

- 3D Systems Inc.

- Desktop Metal Inc.

- EOS GmbH

- Formlabs

- Materialise NV

- Organovo Holding Inc.

- Oxford Performance Materials Inc.

- Prodways Tech

- Proto Labs Inc.

- Renishaw plc

- SLM Solutions Group AG

- Stratasys Ltd

3D Printing in Healthcare Market Report Segmentation:

Breakup By Material:

- Polymer

- Metals

- Ceramic

- Organic

Polymer represents the largest segment due to its versatility, cost-effectiveness, and suitability for a wide range of medical applications, including prosthetics and orthopedic implants.

Breakup By Technology:

- Droplet Deposition

- Fused Filament Fabrication (FFF) Technology

- Low-temperature Deposition Manufacturing (LDM)

- Multiphase Jet Solidification (MJS)

- Photopolymerization

- Stereolithography (SLA)

- Continuous Liquid Interface Production (CLIP)

- Two-photon Polymerization (2PP)

- Laser Beam Melting

- Selective Laser Sintering (SLS)

- Selective Laser Melting (SLM)

- Direct Metal Laser Sintering (DMLS)

- Electronic Beam Melting (EBM)

- Laminated Object Manufacturing

- Others

Droplet deposition accounts for the majority of the market share as it offers high precision and the ability to create complex, patient-specific structures, making it ideal for producing medical devices and implants.

Breakup By Application:

- External Wearable Devices

- Hearing Aids

- Prosthesis and Orthotics

- Dental Products

- Clinical Study Devices

- Drug Testing

- Anatomical Models

- Implants

- Surgical Guides

- Cranio-maxillofacial Implants

- Orthopedic Implants

- Tissue Engineering

External wearable devices exhibit a clear dominance in the market owing to the growing demand for personalized, non-invasive healthcare solutions like custom-fitted hearing aids and smart wearables.

Breakup By End User:

- Medical and Surgical Centers

- Pharmaceutical and Biotechnology Companies

- Academic Institutions

Medical and surgical centers hold the biggest market share, driven by the adoption of 3D printing for creating patient-specific implants, surgical guides, and prosthetics, enhancing patient care and surgical outcomes.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

North America enjoys the leading position in the 3D printing in healthcare market on account of a strong healthcare infrastructure, research and development (R&D) activities, and a growing demand for customized medical solutions in the region.

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145